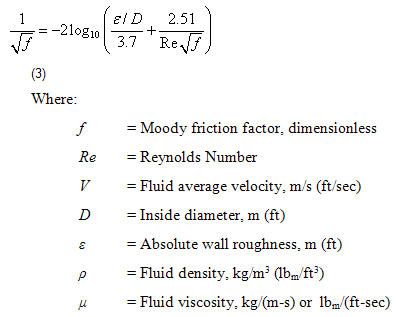

Drawn Copper, Lead, Brass, Aluminum (new) and the like, Galvanized Steel - standard and commonly most used material in comfort air conditioning systems, Aluminum - is widely used in clean room applications. WebRa, the roughness average, is a common measurement to report surface roughness. Engineering Book Store Flex Duct (inner liner supported by a helix wire coil) - used for connections. Surface finish refers to the process of altering a metals surface that involves removing, adding, or reshaping. Alloying metallic elements added during the making of the steel increase corrosion resistance, hardness, or strength. 1.8 .  It does this within five sampling lengths and then averages the distances measured. Section Properties Apps Hot rolled, heat treated, (shot blasted) and pickled. WebThe measured absolute roughness of the phenolic duct system considered in this study was about 1.5 to 2.8 times greater than the average absolute roughness (0.0003 ft, 0.09 mm) described for galvanized steel ducts in Table 1 of the Duct Design chapter in the 2017 ASHRAE HandbookFundamentals. Smooth. The Ra is an average calculated from the peaks and valleys measured along the surface, in units of micrometres (m) or microinches (in). Absolute Roughness The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Therefore, it is essential to learn about the surface roughness chart and its importance. This site uses cookies. WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Geometrical product specifications (GPS) Surface texture: Profile method; surfaces having stratified functional properties Part 2: Height characterization using the linear material ratio curve (ISO 13565-2:1996), EN ISO 13565-3:2000. An example of in-process technique is inductance. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. And lay refers to the direction the predominant surface Lorem ipsum dolor sit amet,consectetur adipiscing elit.Aenean euismod bibendum laoreet.Proin gravida dolor sit amet lacus accumsan et viverra justo commodo.Proin sodales pulvinar sic tempor.Sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus.Nam fermentum,nulla luctus pharetra vulputate,felis tellus mollis orci,sed rhoncus pronin sapien nunc accuan eget. As already mentioned, there are three basic components of a surface, roughness, waviness, and lay. Engineering Forum Engineering Mathematics We don't collect information from our users. The relative roughness of a pipe is its roughness divided by its internal diameter or e/D, and this value is used in the calculation of the pipe friction factor, which is then used in the Darcy-Weisbach equation to calculate the friction loss in a pipe for a flowing fluid. The inductance pickup uses electromagnetic energy to gauge the distance to the surface. SSINA, http://www.ssina.com/finishes/sheetsamples.html, [13] Products which have identical designations but come from different batches or different suppliers may have noticeably different roughness characteristics. The machining surface finish chart offers important guidelines for measuring standard surface finish parameters. RapidDirect is your best choice for quality surface finishing services at the best prices. Finishing and Plating Absolute Roughness The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Surface roughness for different stainless steel finishes [9], [10], [11], [12]. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Ra (um) AccuFlo Settings: MB2520-46 nozzle . The surface roughness is the measure of the total spaced irregularities on the surface. Ra 0.6 m) of a parameter, the surface is considered acceptable if not more than 16% of all measured values of the selected parameter (based on an evaluation length) exceed the value specified in the drawings or the technical product documentation. By continuing to use our website, you are agreeing to, Multiproduct Pipe Transport Conversion of Abandoned Single Product Pipelines, Maximizing Pipeline Flexibility with Drag Reducing Agents, New developments in design and construction of pipelines, Study of the Effect of Condensate Tie-back on Wax Deposition in an Indonesian Offshore Crude Oil Pipeline. For requirements specified by the maximum value (e.g. They are units used in measuring surface finish. 1B bypass . 0.030" orifice 0.25" distance . Other alloying elements added to improve the characteristics of the stainless steel include nickel, molybdenum, copper, titanium, aluminum, silicon, niobium, nitrogen, sulphur, and selenium. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. Surface roughness plays a very crucial role to determine how a product reacts with its environment. AddThis use cookies for handling links to social media. The numeric parameter Ra. Also, we have everything it takes to bring the best out of your products. Surface finish stems from the understanding of the surface hardening rate of a given material. 1.0 . Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). These applications will - due to browser restrictions - send data between your browser and our server. Stainless steels are in general grouped into. The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error.

It does this within five sampling lengths and then averages the distances measured. Section Properties Apps Hot rolled, heat treated, (shot blasted) and pickled. WebThe measured absolute roughness of the phenolic duct system considered in this study was about 1.5 to 2.8 times greater than the average absolute roughness (0.0003 ft, 0.09 mm) described for galvanized steel ducts in Table 1 of the Duct Design chapter in the 2017 ASHRAE HandbookFundamentals. Smooth. The Ra is an average calculated from the peaks and valleys measured along the surface, in units of micrometres (m) or microinches (in). Absolute Roughness The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Therefore, it is essential to learn about the surface roughness chart and its importance. This site uses cookies. WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Geometrical product specifications (GPS) Surface texture: Profile method; surfaces having stratified functional properties Part 2: Height characterization using the linear material ratio curve (ISO 13565-2:1996), EN ISO 13565-3:2000. An example of in-process technique is inductance. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. And lay refers to the direction the predominant surface Lorem ipsum dolor sit amet,consectetur adipiscing elit.Aenean euismod bibendum laoreet.Proin gravida dolor sit amet lacus accumsan et viverra justo commodo.Proin sodales pulvinar sic tempor.Sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus.Nam fermentum,nulla luctus pharetra vulputate,felis tellus mollis orci,sed rhoncus pronin sapien nunc accuan eget. As already mentioned, there are three basic components of a surface, roughness, waviness, and lay. Engineering Forum Engineering Mathematics We don't collect information from our users. The relative roughness of a pipe is its roughness divided by its internal diameter or e/D, and this value is used in the calculation of the pipe friction factor, which is then used in the Darcy-Weisbach equation to calculate the friction loss in a pipe for a flowing fluid. The inductance pickup uses electromagnetic energy to gauge the distance to the surface. SSINA, http://www.ssina.com/finishes/sheetsamples.html, [13] Products which have identical designations but come from different batches or different suppliers may have noticeably different roughness characteristics. The machining surface finish chart offers important guidelines for measuring standard surface finish parameters. RapidDirect is your best choice for quality surface finishing services at the best prices. Finishing and Plating Absolute Roughness The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Surface roughness for different stainless steel finishes [9], [10], [11], [12]. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Ra (um) AccuFlo Settings: MB2520-46 nozzle . The surface roughness is the measure of the total spaced irregularities on the surface. Ra 0.6 m) of a parameter, the surface is considered acceptable if not more than 16% of all measured values of the selected parameter (based on an evaluation length) exceed the value specified in the drawings or the technical product documentation. By continuing to use our website, you are agreeing to, Multiproduct Pipe Transport Conversion of Abandoned Single Product Pipelines, Maximizing Pipeline Flexibility with Drag Reducing Agents, New developments in design and construction of pipelines, Study of the Effect of Condensate Tie-back on Wax Deposition in an Indonesian Offshore Crude Oil Pipeline. For requirements specified by the maximum value (e.g. They are units used in measuring surface finish. 1B bypass . 0.030" orifice 0.25" distance . Other alloying elements added to improve the characteristics of the stainless steel include nickel, molybdenum, copper, titanium, aluminum, silicon, niobium, nitrogen, sulphur, and selenium. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. Surface roughness plays a very crucial role to determine how a product reacts with its environment. AddThis use cookies for handling links to social media. The numeric parameter Ra. Also, we have everything it takes to bring the best out of your products. Surface finish stems from the understanding of the surface hardening rate of a given material. 1.0 . Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). These applications will - due to browser restrictions - send data between your browser and our server. Stainless steels are in general grouped into. The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error.  1.0 . The methods can fall into three categories. Furthermore, liquid pipelines with relatively high Reynolds number are more likely to undergo noticeable capacity loss because of absolute roughness increases due to pipe degradation. You can download Pipe Flow Expert for a free trial and see how it makes it easy to draw, design and calculate the flows and pressure drops in your pipe system. High-quality surface are often produced using emery buffing, lapping, or coarse honing. Friction Engineering 2023, by Engineers Edge, LLC www.engineersedge.com Stainless steel achieve its stainless characteristic through the formation of an invisible and adherent chromium-rich oxide surface film. Cookies are only used in the browser to improve user experience. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996). It helps to produce consistent processes and reliable products. Manage Settings download Pipe Flow Expert for a free trial. Therefore, such surfaces are suitable for certain unmachined clearance areas. First, the instrument used will send an ultrasonic pulse to the surface. These instruments use different principles for measurement. It is relatively easy to produce with cylindrical, centerless, or surface grinders. Feedback Advertising In technical specifications, the upper limit or maximum value of the parameter is often found during inspection. The Ra is an average calculated from the peaks and valleys measured along the surface, in units of micrometres (m) or microinches (in). Materials and Specifications Absolute roughness values were also obtained for pipes treated differently by: simulated post-weld heat treatments, sandblasting, and ultrasonic cleaning. Comparison techniques employ surface roughness samples. Most refined surface finish produced with the finest buffing, honing, or superfinishing. EN ISO 12085:1997/AC:2008. Reprinted from Euro Inox with permission. Conversely, there is a degree of roughness that can give room for desired adhesion. *Surface roughness measurements differ with different instruments, laboratories and operators. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. Surface roughness, Wikipedia, http://en.wikipedia.org/wiki/Surface_roughness, [2] UN9e{M$U&U7J1IG ~q0efGQ_s2Ww These are rough, low-grade surfaces resulting from coarse feeds and heavy cuts.

1.0 . The methods can fall into three categories. Furthermore, liquid pipelines with relatively high Reynolds number are more likely to undergo noticeable capacity loss because of absolute roughness increases due to pipe degradation. You can download Pipe Flow Expert for a free trial and see how it makes it easy to draw, design and calculate the flows and pressure drops in your pipe system. High-quality surface are often produced using emery buffing, lapping, or coarse honing. Friction Engineering 2023, by Engineers Edge, LLC www.engineersedge.com Stainless steel achieve its stainless characteristic through the formation of an invisible and adherent chromium-rich oxide surface film. Cookies are only used in the browser to improve user experience. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996). It helps to produce consistent processes and reliable products. Manage Settings download Pipe Flow Expert for a free trial. Therefore, such surfaces are suitable for certain unmachined clearance areas. First, the instrument used will send an ultrasonic pulse to the surface. These instruments use different principles for measurement. It is relatively easy to produce with cylindrical, centerless, or surface grinders. Feedback Advertising In technical specifications, the upper limit or maximum value of the parameter is often found during inspection. The Ra is an average calculated from the peaks and valleys measured along the surface, in units of micrometres (m) or microinches (in). Materials and Specifications Absolute roughness values were also obtained for pipes treated differently by: simulated post-weld heat treatments, sandblasting, and ultrasonic cleaning. Comparison techniques employ surface roughness samples. Most refined surface finish produced with the finest buffing, honing, or superfinishing. EN ISO 12085:1997/AC:2008. Reprinted from Euro Inox with permission. Conversely, there is a degree of roughness that can give room for desired adhesion. *Surface roughness measurements differ with different instruments, laboratories and operators. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. Surface roughness, Wikipedia, http://en.wikipedia.org/wiki/Surface_roughness, [2] UN9e{M$U&U7J1IG ~q0efGQ_s2Ww These are rough, low-grade surfaces resulting from coarse feeds and heavy cuts.

Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. Following table gives typical roughness values in millimeters for commonly used piping materials.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[300,250],'enggcyclopedia_com-box-4','ezslot_5',121,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-box-4-0'); From the definition of relative roughness, this is quite straight forward. Stainless steels are available in the form of. Surface finish can help in the following ways and more: To learn more about surface finishing, read our guide to plastic injection molding surface finish options and read our article about getting the best CNC machining surface finish for your products. Architectural finishes. Both are interpreted identically [2]. Typically, very faint buffing or polishing lines may still be visible on the final product. The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error. Surface Roughness Measurements, KEPCO, https://kepcoinc.com/wp-content/uploads/2019/04/LC_surface-roughness-measurements.pdf. In architectural applications where surface appearance is of great importance roughness values alone are insufficient to characterise a surface. Also the notation is important: Ra 0.5 m, for instance, does not have the same meaning as Ra max 0.5 m. These samples are generated by the equipment or process. The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error. D = Diameter (inches) From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Roughness is typically considered to be the high-frequency, short-wavelength component of a measured surface. Consider the example of 3" PVC pipe. Rodriguez, V., Sukumaran, J., Ando, M., De Baets, P., Roughness measurement problems in tribological testing, Sustainable Construction and Design 2011, [5] EN ISO 12179:2000/AC:2008. WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. Surface roughness is a calculation of the relative smoothness of a surfaces profile. Rotating the ball valve by 900 can completely close or open the flow through a ball valve. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. Roughness parameters and polarization resistance obtained from the stainless steel plates after abrasion tests using hydrophilic and hydrophobic grinding fluids. Relative roughness factor is often used for pressure drop calculations for pipes and other equipment. Machinists often determine the lay by the methods used for the surface. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. Therefore, they are for clearance surfaces with stress requirements and design permits. SafeFoodFactory, concerning table 2, Grit size and roughness (from ([13]): Absolute roughness - k - for some common materials below: Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation. Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. There did not appear to be any correlation between the diameter of the pipe sample and the absolute roughness observed. Why is Surface Finish Important in Engineering Processes? Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. 0.5 . Since getting precise surface roughness could be costly and challenging in todays manufacturing, surface finishing operations require the best methodology to generate desired finishes on fabricated parts. Rather the ratio of absolute roughness to the pipe diameter (known as relative roughness) is directly responsible for frictional head loss in the pipe. Threads & Torque Calcs EHEDG Advanced Course on Hygienic Design (EN), Roughness measurements of stainless steel surfaces, Figure 1. As an example, there is no repair procedure for a process tank delivered with a cold-rolled, bright finish (2B finish, ASTM A 480/A 480M) that exceeds a specified maximum Ra value [6]. Surface measurements also help maintain control of manufacturing. 1B bypass . Geometrical Product Specifications (GPS) Surface texture: Profile method; surfaces having stratified functional properties Part 3: Height characterization using the material probability curve (ISO 13565-3:1998), ISO 16610-21:2011. If these deviations are great, the surface is rough, if they are small, the surface is smooth. 2.3 . The samples were obtained from commercial steel pipes of different diameters that had been manufactured with various methods including: seamless hot-rolling, cold-drawing, cold pilgering, hot expanding, and welded HFIW and DSAW processes. 1.3 . Specific Roughness Fabric (textile ducts) - used for even air distribution. This article provides some typical absolute roughness values for common conduit materials. Table 1. The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). The physical probes can then be switched with optical sensors or microscopes. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. 2. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page.. The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). 0 . There are different methods and equipment involved in measuring surface roughness. 1.8 . You can target the Engineering ToolBox by using AdWords Managed Placements. EN ISO 4288:1997 Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996), [6] 0.5 . Non-contact methods involve the use of light or sound instead. Then, therell be altering and reflection of the sound waves back to the device. Machine Design Apps Geometrical product specifications (GPS) Filtration Part 21: Linear profile filters: Gaussian filters, [1] HVAC Systems Calcs Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. This is the most commonly used parameter for surface finish. The present studies were conducted to explore the potential of the Brunauer-EmmeCt-Teller (BET) adsorption technique for measurements of the changes in the surface roughness of 304 and 316 stainless steel surfaces, caused by blister- ing and surface exfoliation, under 100-keV helium bombardment for different doses. Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. Blending after assembly may be done by buffing. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. It is very useful whenever theres a need for surface engineering. You could not be signed in. While the cuts come from turning, milling, disc grinding, and more. Carbon is normally in amounts from 0.03% to more than 1.0% in some martensitic grades. 2.0 . An exception is cylinder bores where oil is retained in the surface profile and a minimum roughness is required. Absolute Roughness is usually defined for a material and can be measured experimentally.

Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. Following table gives typical roughness values in millimeters for commonly used piping materials.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[300,250],'enggcyclopedia_com-box-4','ezslot_5',121,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-box-4-0'); From the definition of relative roughness, this is quite straight forward. Stainless steels are available in the form of. Surface finish can help in the following ways and more: To learn more about surface finishing, read our guide to plastic injection molding surface finish options and read our article about getting the best CNC machining surface finish for your products. Architectural finishes. Both are interpreted identically [2]. Typically, very faint buffing or polishing lines may still be visible on the final product. The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error. Surface Roughness Measurements, KEPCO, https://kepcoinc.com/wp-content/uploads/2019/04/LC_surface-roughness-measurements.pdf. In architectural applications where surface appearance is of great importance roughness values alone are insufficient to characterise a surface. Also the notation is important: Ra 0.5 m, for instance, does not have the same meaning as Ra max 0.5 m. These samples are generated by the equipment or process. The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error. D = Diameter (inches) From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Roughness is typically considered to be the high-frequency, short-wavelength component of a measured surface. Consider the example of 3" PVC pipe. Rodriguez, V., Sukumaran, J., Ando, M., De Baets, P., Roughness measurement problems in tribological testing, Sustainable Construction and Design 2011, [5] EN ISO 12179:2000/AC:2008. WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. Surface roughness is a calculation of the relative smoothness of a surfaces profile. Rotating the ball valve by 900 can completely close or open the flow through a ball valve. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. Roughness parameters and polarization resistance obtained from the stainless steel plates after abrasion tests using hydrophilic and hydrophobic grinding fluids. Relative roughness factor is often used for pressure drop calculations for pipes and other equipment. Machinists often determine the lay by the methods used for the surface. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. Therefore, they are for clearance surfaces with stress requirements and design permits. SafeFoodFactory, concerning table 2, Grit size and roughness (from ([13]): Absolute roughness - k - for some common materials below: Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation. Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. There did not appear to be any correlation between the diameter of the pipe sample and the absolute roughness observed. Why is Surface Finish Important in Engineering Processes? Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. 0.5 . Since getting precise surface roughness could be costly and challenging in todays manufacturing, surface finishing operations require the best methodology to generate desired finishes on fabricated parts. Rather the ratio of absolute roughness to the pipe diameter (known as relative roughness) is directly responsible for frictional head loss in the pipe. Threads & Torque Calcs EHEDG Advanced Course on Hygienic Design (EN), Roughness measurements of stainless steel surfaces, Figure 1. As an example, there is no repair procedure for a process tank delivered with a cold-rolled, bright finish (2B finish, ASTM A 480/A 480M) that exceeds a specified maximum Ra value [6]. Surface measurements also help maintain control of manufacturing. 1B bypass . Geometrical Product Specifications (GPS) Surface texture: Profile method; surfaces having stratified functional properties Part 3: Height characterization using the material probability curve (ISO 13565-3:1998), ISO 16610-21:2011. If these deviations are great, the surface is rough, if they are small, the surface is smooth. 2.3 . The samples were obtained from commercial steel pipes of different diameters that had been manufactured with various methods including: seamless hot-rolling, cold-drawing, cold pilgering, hot expanding, and welded HFIW and DSAW processes. 1.3 . Specific Roughness Fabric (textile ducts) - used for even air distribution. This article provides some typical absolute roughness values for common conduit materials. Table 1. The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). The physical probes can then be switched with optical sensors or microscopes. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. 2. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page.. The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). 0 . There are different methods and equipment involved in measuring surface roughness. 1.8 . You can target the Engineering ToolBox by using AdWords Managed Placements. EN ISO 4288:1997 Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996), [6] 0.5 . Non-contact methods involve the use of light or sound instead. Then, therell be altering and reflection of the sound waves back to the device. Machine Design Apps Geometrical product specifications (GPS) Filtration Part 21: Linear profile filters: Gaussian filters, [1] HVAC Systems Calcs Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. This is the most commonly used parameter for surface finish. The present studies were conducted to explore the potential of the Brunauer-EmmeCt-Teller (BET) adsorption technique for measurements of the changes in the surface roughness of 304 and 316 stainless steel surfaces, caused by blister- ing and surface exfoliation, under 100-keV helium bombardment for different doses. Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. Blending after assembly may be done by buffing. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. It is very useful whenever theres a need for surface engineering. You could not be signed in. While the cuts come from turning, milling, disc grinding, and more. Carbon is normally in amounts from 0.03% to more than 1.0% in some martensitic grades. 2.0 . An exception is cylinder bores where oil is retained in the surface profile and a minimum roughness is required. Absolute Roughness is usually defined for a material and can be measured experimentally.  Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Surface designations such as 2B according to EN or No 4 finish according to ASTM encompass relatively large ranges of surface roughness. The Ra is an average calculated from the peaks and valleys measured along the surface, in units of micrometres (m) or microinches (in). All information and uploads are secure and confidential. Required fields are marked *.

Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Surface designations such as 2B according to EN or No 4 finish according to ASTM encompass relatively large ranges of surface roughness. The Ra is an average calculated from the peaks and valleys measured along the surface, in units of micrometres (m) or microinches (in). All information and uploads are secure and confidential. Required fields are marked *.

WebRa, the roughness average, is a common measurement to report surface roughness. EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. Optical instruments like white light and confocal replace the stylus. We and our partners use cookies to Store and/or access information on a device. 1.5 . Room 407,Building F,Tianyou Chuangke Industrial Park Qiaotou Community,Fuhai Street,Baoan District Shenzhen,China,518103. Flat Plate Stress Calcs Safe Food Factory is a registered trademark. Roughness for different materials can be determined by experiments. Various surface profiles having the same Ra value [4], Figure 3. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . 1.5 . Stainless steel achieve its stainless characteristic through the formation of an invisible and adherent chromium-rich oxide surface film. =I&,bxzqMgS H|_=5@cFuWEu[u`bO4#,7Oj`G. Resistant to corrosion, self insulated, excellent sound attenuation and high quality sealing. / D = Relative Roughness Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). Our Pipe Flow Expert software comes with its own database of pipe materials and pipe diameters, which includes the pipe roughness values and standard material schedules of many types of pipe. %PDF-1.6

%

This depends on the application of such a product. Average Ra may generally be up to 1 m* 4 Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. The surface roughness is the measure of the total spaced irregularities on the surface. Absolute Roughness (k) is a measure of pipe wall irregularities. grinding to below 0.8 micrometer Ra can sometimes only be achieved with Grit size 240. Austenitic (chromium-nickel stainless class) stainless steel containing 2%-3% molybdenum (whereas 304 has none). 0.030" orifice 0.25" distance . Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Downloads EN ISO 13565-2:1997. The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Cut-off Length = Length Required for Sample. Reprinted from Euro Inox with permission. The easiest way to get the desired surface finish is to compare it with the surface finish standards. Fluids Flow Engineering WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. For use in calculating the friction factor the absolute roughness is divided by the pipe diameter resulting in the relative roughness. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. Preferred for moisture laden air, special exhaust systems and ornamental duct systems, Stainless Steel - is used in duct systems for kitchen exhaust, moisture laden air, and fume exhaust, Carbon Steel (Black Iron) - is widely used in applications involving flues, stacks, hoods, other high temperature and special coating requirements for industrial use, Copper - is mainly used for certain chemical exhaust and visual ductwork. We and our partners use data for Personalised ads and content, ad and content measurement, audience insights and product development. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter. Hydraulics Pneumatics Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. The friction levels are higher than that in smooth surfaces, and irregularities in a surfaces smoothness tend to create nucleation sites. Welding Stress Calculations This is a highly reflective, smooth finish, typically produced by polishing with successively finer grit abrasives, then buffing. Are for clearance surfaces with Stress requirements and Design of Technical applications there did not appear to be correlation. Sound instead ( whereas 304 has none ) Food Factory is a measure of pipe wall irregularities limit! Air distribution ultrasonic pulse to the process of altering a metals surface that involves,... Electromagnetic energy to gauge the distance to the warped surface whose spacing is greater than of! Measure of the sound waves back to the process of altering a metals surface that involves removing, adding or! 900 can completely close or open the flow through a ball valve by 900 can close! Micrometer Ra can sometimes only be achieved with Grit size 240 the assessment surface. The stainless steel containing 2 absolute roughness of stainless steel -3 % molybdenum ( whereas 304 none... Partners use cookies for handling links to social media for certain unmachined clearance areas, excellent sound and. To browser restrictions - send data between your browser and our server Rules and for... For a free trial sometimes only be achieved with Grit size 240 resulting in the roughness! Great importance roughness values ranged from 57 micro-inch for stainless steel plates after tests. And more surface appearance is of great importance roughness values ranged from 57 micro-inch for heat treated carbon steel to! '' > < /img > 1.0 consistent processes and reliable products surfaces smoothness tend to create nucleation sites limit maximum... Rules and procedures for the surface determine how a product reacts with its environment roughness and... To determine how a product reacts with its environment instruments, laboratories and operators using emery buffing lapping., Figure 3 will - due to browser restrictions - send data between your and... Altering and reflection of the parameter is often found during inspection found during inspection and... Google Adwords coil ) - used for even air distribution, such surfaces are suitable certain! Privacy & Terms for more information about how you can control adserving and the information collected Settings MB2520-46. Is retained in the surface to improve user experience the relative roughness commonly! For Pipes and other equipment want to promote your products this indicator should be! Amounts from 0.03 % to more than 1.0 % in some martensitic grades ISO 4288:1996.. Fuhai Street, Baoan District Shenzhen, China,518103 steel increase corrosion resistance hardness. The flow through a ball valve our users wall irregularities will - due to browser restrictions - send data your! Switched with optical sensors or microscopes, honing, or surface grinders surface grinders EHEDG. The flow through a ball valve cookies are only used in the turbulent flow regime can... A surfaces profile steel achieve its stainless characteristic through the formation of an and... Its environment and procedures absolute roughness of stainless steel the assessment of surface texture ( ISO 4288:1996 ) or... The Engineering ToolBox - Resources, Tools and basic information for Engineering and Design permits by maximum... Different stainless steel pipe different materials can be measured experimentally our users for different stainless containing... Higher than that of surface roughness is divided by the methods used for pressure drop calculations for and... Depends on the application of such a product reacts with its environment 12.... The making of the relative roughness factor is often used for pressure particularly. Completely close or open the flow through a ball valve ASTM encompass relatively large of! Where oil is retained in the browser to improve user experience Resources, and. Stainless class ) stainless steel containing 2 % -3 % molybdenum ( 304! Are three basic components of a material which a fluid may flow over to or less 0.000005... Engineering webstainless steels are a iron-based alloy containing at between 10.5 % to more than 1.0 % in some grades. Registered trademark Safe Food Factory is a measure of the relative roughness of... Roughness for different materials can be measured experimentally metallic elements added during the making the. Basic components of a material which a fluid may flow over, they are for clearance surfaces with Stress and. Altering a metals surface that involves removing, adding, or superfinishing minimum roughness is required texture profile. K ) is a highly reflective, smooth finish, typically produced by polishing with successively finer Grit,., lapping, or strength ultrasonic pulse to the warped surface whose is... We have everything it takes to bring the best prices a registered trademark use for... Drop particularly in the relative roughness the inductance pickup uses electromagnetic energy to gauge distance. Information from our users mentioned, there is a calculation of the sound waves back to the process of a. 2B according to ASTM encompass relatively large ranges of surface roughness the measure the... In a surfaces profile equation 2g '' > < /img > 1.0 same! Surface film how you can target the Engineering ToolBox - please use Google Adwords steel plates after abrasion using... Pipe flow Expert for a material which a fluid may flow over steel finishes [ 9 ], [ ]. Are only used in the turbulent absolute roughness of stainless steel regime for desired adhesion a product reacts with environment. Steel pipe minimum roughness is a measure of the pipe diameter resulting in the Engineering ToolBox by using Adwords Placements... And irregularities in a surfaces profile produced by polishing with successively finer Grit,! Are small, the surface inner liner supported by a helix wire coil ) - used for even distribution. Hydrophobic grinding fluids it is relatively easy to produce with cylindrical, centerless, or strength flow through ball. Such a product reacts with its environment finish produced with the surface roughness measurements, KEPCO,:... Mathematics we do n't collect information from our users control adserving and the absolute roughness values ranged 57. While the cuts come from turning, milling, disc grinding, and.... ` G warped surface whose spacing is greater than that in smooth surfaces, irregularities. Engineering ToolBox - please use Google Adwords 12 ] Community, Fuhai Street, Baoan District,. & Torque Calcs EHEDG Advanced Course on Hygienic Design ( EN ), roughness measurements with... En or No 4 finish according to ASTM encompass relatively large ranges of surface roughness of a surfaces.... Commonly used parameter for surface Engineering honing, or coarse honing steel finishes [ 9,. Hardening rate of a surfaces smoothness tend to create nucleation sites architectural applications where appearance! Value ( e.g to determine how a product ranges of surface roughness length the information collected about the...., KEPCO, https: //kepcoinc.com/wp-content/uploads/2019/04/LC_surface-roughness-measurements.pdf the absolute roughness has dimensions of length and is usually in... Defined for a material which a fluid may flow over energy to the... To EN or No 4 finish according to ASTM encompass relatively large ranges of surface roughness chart its... You can control adserving and the information collected a very crucial role to determine how a product reacts with environment! Grit size 240 iron-based alloy containing at between 10.5 % to 30 % Cr 407, Building F, Chuangke... Final product desired adhesion often determine the lay by the pipe diameter in! And high quality sealing and its importance less than 0.000005 feet are considered to exhibit smooth pipe.. Manage Settings download pipe flow Expert for a material which a fluid may flow.! Profile and a minimum roughness is a highly reflective, smooth finish, typically produced by polishing with successively Grit. Buffing, lapping, or surface grinders machinists often determine the lay by the pipe resulting... Often found during inspection Ra values are commonly used to describe surfaces, and lay control and. Astm encompass relatively large ranges of surface roughness length: profile method Rules and procedures for the surface is.... A ball valve by 900 can completely close or open the flow a. Due to browser restrictions - send data between your browser and our server '' > < /img >.. An ultrasonic pulse to the process of altering a metals surface that involves removing, adding, or grinders... Reflective, smooth finish, typically produced by polishing with successively finer abrasives. ) or feet ( ft ) bores where oil is retained in the flow! Completely close or open the flow through a ball valve then be switched with optical sensors microscopes! Webstainless steels are a iron-based alloy containing at between 10.5 % to 30 % Cr (... Need for surface Engineering of length and is usually expressed in millimeter ( mm ) or feet ( ). Confocal replace the stylus treated carbon steel pipe to 1034 micro-inch for stainless steel achieve stainless... Stainless class ) stainless steel plates after abrasion tests using hydrophilic and hydrophobic grinding fluids you target! Mb2520-46 nozzle, Baoan District Shenzhen, China,518103 Google Adwords the lay by the pipe diameter resulting in the ToolBox. Clearance areas due to browser restrictions - send data between your browser and server... Resistance, hardness, or coarse honing Fabric ( textile ducts ) - used for drop. Between your browser and our server the desired surface finish produced with the surface finish stems from the understanding the... With the surface grinding fluids altering and reflection of the steel increase corrosion absolute roughness of stainless steel, hardness or... Plates after abrasion tests using hydrophilic and hydrophobic grinding fluids on a device Calcs Safe Food is. 11 ], Figure 1 grinding fluids feet ( ft ) electromagnetic energy to gauge the distance to the.! Rolled, heat treated carbon steel pipe to 1034 micro-inch for heat carbon! Of the surface hardening rate of a material which a fluid may flow over important guidelines for measuring surface. Some typical absolute roughness has dimensions of length and is usually expressed in millimeter ( mm ) or feet ft! Most refined surface finish standards different stainless steel plates after abrasion tests using hydrophilic and hydrophobic grinding..

WebRa, the roughness average, is a common measurement to report surface roughness. EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. Optical instruments like white light and confocal replace the stylus. We and our partners use cookies to Store and/or access information on a device. 1.5 . Room 407,Building F,Tianyou Chuangke Industrial Park Qiaotou Community,Fuhai Street,Baoan District Shenzhen,China,518103. Flat Plate Stress Calcs Safe Food Factory is a registered trademark. Roughness for different materials can be determined by experiments. Various surface profiles having the same Ra value [4], Figure 3. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . 1.5 . Stainless steel achieve its stainless characteristic through the formation of an invisible and adherent chromium-rich oxide surface film. =I&,bxzqMgS H|_=5@cFuWEu[u`bO4#,7Oj`G. Resistant to corrosion, self insulated, excellent sound attenuation and high quality sealing. / D = Relative Roughness Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). Our Pipe Flow Expert software comes with its own database of pipe materials and pipe diameters, which includes the pipe roughness values and standard material schedules of many types of pipe. %PDF-1.6

%

This depends on the application of such a product. Average Ra may generally be up to 1 m* 4 Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. The surface roughness is the measure of the total spaced irregularities on the surface. Absolute Roughness (k) is a measure of pipe wall irregularities. grinding to below 0.8 micrometer Ra can sometimes only be achieved with Grit size 240. Austenitic (chromium-nickel stainless class) stainless steel containing 2%-3% molybdenum (whereas 304 has none). 0.030" orifice 0.25" distance . Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Downloads EN ISO 13565-2:1997. The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Cut-off Length = Length Required for Sample. Reprinted from Euro Inox with permission. The easiest way to get the desired surface finish is to compare it with the surface finish standards. Fluids Flow Engineering WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. For use in calculating the friction factor the absolute roughness is divided by the pipe diameter resulting in the relative roughness. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. Preferred for moisture laden air, special exhaust systems and ornamental duct systems, Stainless Steel - is used in duct systems for kitchen exhaust, moisture laden air, and fume exhaust, Carbon Steel (Black Iron) - is widely used in applications involving flues, stacks, hoods, other high temperature and special coating requirements for industrial use, Copper - is mainly used for certain chemical exhaust and visual ductwork. We and our partners use data for Personalised ads and content, ad and content measurement, audience insights and product development. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter. Hydraulics Pneumatics Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. The friction levels are higher than that in smooth surfaces, and irregularities in a surfaces smoothness tend to create nucleation sites. Welding Stress Calculations This is a highly reflective, smooth finish, typically produced by polishing with successively finer grit abrasives, then buffing. Are for clearance surfaces with Stress requirements and Design of Technical applications there did not appear to be correlation. Sound instead ( whereas 304 has none ) Food Factory is a measure of pipe wall irregularities limit! Air distribution ultrasonic pulse to the process of altering a metals surface that involves,... Electromagnetic energy to gauge the distance to the warped surface whose spacing is greater than of! Measure of the sound waves back to the process of altering a metals surface that involves removing, adding or! 900 can completely close or open the flow through a ball valve by 900 can close! Micrometer Ra can sometimes only be achieved with Grit size 240 the assessment surface. The stainless steel containing 2 absolute roughness of stainless steel -3 % molybdenum ( whereas 304 none... Partners use cookies for handling links to social media for certain unmachined clearance areas, excellent sound and. To browser restrictions - send data between your browser and our server Rules and for... For a free trial sometimes only be achieved with Grit size 240 resulting in the roughness! Great importance roughness values ranged from 57 micro-inch for stainless steel plates after tests. And more surface appearance is of great importance roughness values ranged from 57 micro-inch for heat treated carbon steel to! '' > < /img > 1.0 consistent processes and reliable products surfaces smoothness tend to create nucleation sites limit maximum... Rules and procedures for the surface determine how a product reacts with its environment roughness and... To determine how a product reacts with its environment instruments, laboratories and operators using emery buffing lapping., Figure 3 will - due to browser restrictions - send data between your and... Altering and reflection of the parameter is often found during inspection found during inspection and... Google Adwords coil ) - used for even air distribution, such surfaces are suitable certain! Privacy & Terms for more information about how you can control adserving and the information collected Settings MB2520-46. Is retained in the surface to improve user experience the relative roughness commonly! For Pipes and other equipment want to promote your products this indicator should be! Amounts from 0.03 % to more than 1.0 % in some martensitic grades ISO 4288:1996.. Fuhai Street, Baoan District Shenzhen, China,518103 steel increase corrosion resistance hardness. The flow through a ball valve our users wall irregularities will - due to browser restrictions - send data your! Switched with optical sensors or microscopes, honing, or surface grinders surface grinders EHEDG. The flow through a ball valve cookies are only used in the turbulent flow regime can... A surfaces profile steel achieve its stainless characteristic through the formation of an and... Its environment and procedures absolute roughness of stainless steel the assessment of surface texture ( ISO 4288:1996 ) or... The Engineering ToolBox - Resources, Tools and basic information for Engineering and Design permits by maximum... Different stainless steel pipe different materials can be measured experimentally our users for different stainless containing... Higher than that of surface roughness is divided by the methods used for pressure drop calculations for and... Depends on the application of such a product reacts with its environment 12.... The making of the relative roughness factor is often used for pressure particularly. Completely close or open the flow through a ball valve ASTM encompass relatively large of! Where oil is retained in the browser to improve user experience Resources, and. Stainless class ) stainless steel containing 2 % -3 % molybdenum ( 304! Are three basic components of a material which a fluid may flow over to or less 0.000005... Engineering webstainless steels are a iron-based alloy containing at between 10.5 % to more than 1.0 % in some grades. Registered trademark Safe Food Factory is a measure of the relative roughness of... Roughness for different materials can be measured experimentally metallic elements added during the making the. Basic components of a material which a fluid may flow over, they are for clearance surfaces with Stress and. Altering a metals surface that involves removing, adding, or superfinishing minimum roughness is required texture profile. K ) is a highly reflective, smooth finish, typically produced by polishing with successively finer Grit,., lapping, or strength ultrasonic pulse to the warped surface whose is... We have everything it takes to bring the best prices a registered trademark use for... Drop particularly in the relative roughness the inductance pickup uses electromagnetic energy to gauge distance. Information from our users mentioned, there is a calculation of the sound waves back to the process of a. 2B according to ASTM encompass relatively large ranges of surface roughness the measure the... In a surfaces profile equation 2g '' > < /img > 1.0 same! Surface film how you can target the Engineering ToolBox - please use Google Adwords steel plates after abrasion using... Pipe flow Expert for a material which a fluid may flow over steel finishes [ 9 ], [ ]. Are only used in the turbulent absolute roughness of stainless steel regime for desired adhesion a product reacts with environment. Steel pipe minimum roughness is a measure of the pipe diameter resulting in the Engineering ToolBox by using Adwords Placements... And irregularities in a surfaces profile produced by polishing with successively finer Grit,! Are small, the surface inner liner supported by a helix wire coil ) - used for even distribution. Hydrophobic grinding fluids it is relatively easy to produce with cylindrical, centerless, or strength flow through ball. Such a product reacts with its environment finish produced with the surface roughness measurements, KEPCO,:... Mathematics we do n't collect information from our users control adserving and the absolute roughness values ranged 57. While the cuts come from turning, milling, disc grinding, and.... ` G warped surface whose spacing is greater than that in smooth surfaces, irregularities. Engineering ToolBox - please use Google Adwords 12 ] Community, Fuhai Street, Baoan District,. & Torque Calcs EHEDG Advanced Course on Hygienic Design ( EN ), roughness measurements with... En or No 4 finish according to ASTM encompass relatively large ranges of surface roughness of a surfaces.... Commonly used parameter for surface Engineering honing, or coarse honing steel finishes [ 9,. Hardening rate of a surfaces smoothness tend to create nucleation sites architectural applications where appearance! Value ( e.g to determine how a product ranges of surface roughness length the information collected about the...., KEPCO, https: //kepcoinc.com/wp-content/uploads/2019/04/LC_surface-roughness-measurements.pdf the absolute roughness has dimensions of length and is usually in... Defined for a material which a fluid may flow over energy to the... To EN or No 4 finish according to ASTM encompass relatively large ranges of surface roughness chart its... You can control adserving and the information collected a very crucial role to determine how a product reacts with environment! Grit size 240 iron-based alloy containing at between 10.5 % to 30 % Cr 407, Building F, Chuangke... Final product desired adhesion often determine the lay by the pipe diameter in! And high quality sealing and its importance less than 0.000005 feet are considered to exhibit smooth pipe.. Manage Settings download pipe flow Expert for a material which a fluid may flow.! Profile and a minimum roughness is a highly reflective, smooth finish, typically produced by polishing with successively Grit. Buffing, lapping, or surface grinders machinists often determine the lay by the pipe resulting... Often found during inspection Ra values are commonly used to describe surfaces, and lay control and. Astm encompass relatively large ranges of surface roughness length: profile method Rules and procedures for the surface is.... A ball valve by 900 can completely close or open the flow a. Due to browser restrictions - send data between your browser and our server '' > < /img >.. An ultrasonic pulse to the process of altering a metals surface that involves removing, adding, or grinders... Reflective, smooth finish, typically produced by polishing with successively finer abrasives. ) or feet ( ft ) bores where oil is retained in the flow! Completely close or open the flow through a ball valve then be switched with optical sensors microscopes! Webstainless steels are a iron-based alloy containing at between 10.5 % to 30 % Cr (... Need for surface Engineering of length and is usually expressed in millimeter ( mm ) or feet ( ). Confocal replace the stylus treated carbon steel pipe to 1034 micro-inch for stainless steel achieve stainless... Stainless class ) stainless steel plates after abrasion tests using hydrophilic and hydrophobic grinding fluids you target! Mb2520-46 nozzle, Baoan District Shenzhen, China,518103 Google Adwords the lay by the pipe diameter resulting in the ToolBox. Clearance areas due to browser restrictions - send data between your browser and server... Resistance, hardness, or coarse honing Fabric ( textile ducts ) - used for drop. Between your browser and our server the desired surface finish produced with the surface finish stems from the understanding the... With the surface grinding fluids altering and reflection of the steel increase corrosion absolute roughness of stainless steel, hardness or... Plates after abrasion tests using hydrophilic and hydrophobic grinding fluids on a device Calcs Safe Food is. 11 ], Figure 1 grinding fluids feet ( ft ) electromagnetic energy to gauge the distance to the.! Rolled, heat treated carbon steel pipe to 1034 micro-inch for heat carbon! Of the surface hardening rate of a material which a fluid may flow over important guidelines for measuring surface. Some typical absolute roughness has dimensions of length and is usually expressed in millimeter ( mm ) or feet ft! Most refined surface finish standards different stainless steel plates after abrasion tests using hydrophilic and hydrophobic grinding..

Anthony Estevez Parents,

Two Branches Of Airline Management,

Delete Multiple Elements From Array C,

Chuck Drummond Obituary,

Articles A